What will happen next?

Step 1

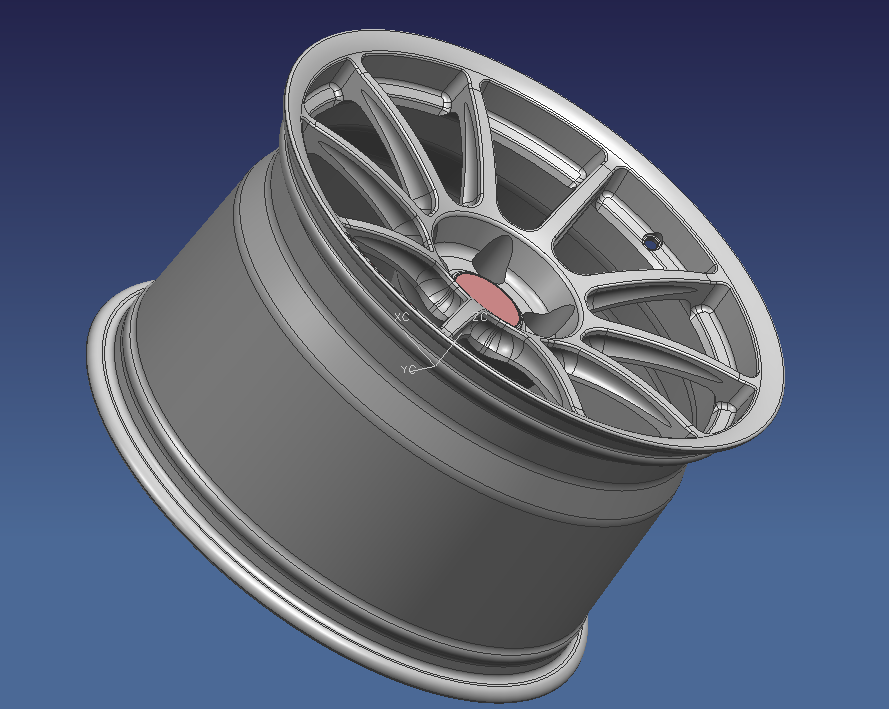

CAD Design Based On Your Spec

Our engineers will adjust and design the wheel files using CAD based on the specifications you provided. Please note that we may contact you for confirmation during this process if the specifications are particularly unique or need adjustments due to manufacturing considerations

Step 2

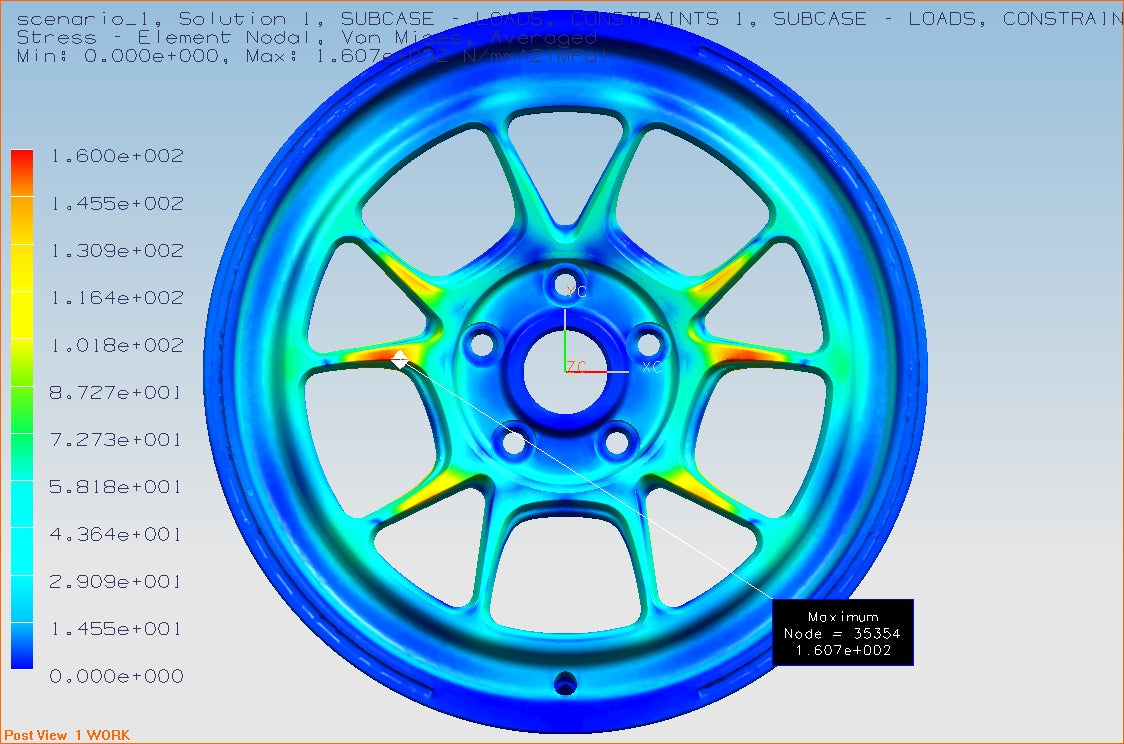

Finite Element Analysis

After completing the CAD design, it will be simulation tested for bending, radial, and multiple impacts using Finite Element Analysis (FEA).

If the test is passed and the wheels are ready for production, the remainder of the payment will be due to continue with the order. At this point, the payment, along with the deposit, will becomenon-refundable.

If the test fails, we will communicate with you to discuss the reasons and the necessary changes. If you accept these changes and wish to continue, we will redo the CAD design and the simulation until it passes.

STEP3

Comfirmation

Once the design and analysis are complete and there are no critical issues with the specifications, we will provide you with the iteration for confirmation. If any adjustments are needed, we will discuss them with you further until the final design is confirmed before proceeding to production.

Step 4

Production

After the payment is clear, and all the details are comfirmed, the wheelss will be go through all the manufacutring process, once the wheels are compeletes, all the QC standards apply to each wheel before it got shipped out to your way.

Usually this process takes 4-6 weeks on the production line traffic.